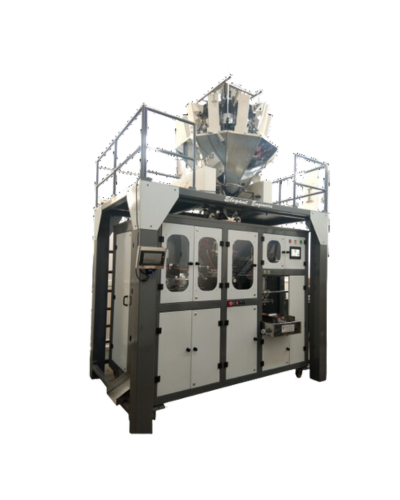

Box Motion Sealer for Quad (four-corner seal) pouches with continuous motion and vacuum pulling. Produces up to 80 pouches/min, servo-controlled for smooth operation, supports multiple filling options, and handles roll widths up to 400 mm.

Automatic high speed continuous box-motion, vacuum pulling VFFS ( Collar type ) machine ( Model No.- PackBot-50)

1. Box Motion sealers, suitable to make center seal / side gusset pouches.

2. Vacuum pulling, Continuous motion.

3. Upto 140 Pouches / min. (As per product & weight).

4. 3 / 4 Servo Motors Controlled.

5. Filling options - Multihead weigher, Servo Auger, Volumetric cup filler.

6. Latest Technology, Smooth Operation.

7. Upto 520 mm. roll width.

8. Power Needs - 440 VAC, 7 kW.

9. Compresses air needs- 2 - 3 cfm @ 6 bar.

Box Motion Sealer for Quad (four-corner seal) pouches with continuous motion and vacuum pulling. Produces up to 80 pouches/min, servo-controlled for smooth operation, supports multiple filling options, and handles roll widths up to 400 mm.

1. Box Motion sealers, suitable to make Quad (Four corner seal) pouches.

2. Vacuum pulling, Continuous motion.

3. Upto 80 Pouches/min. (As per product & weight).

4. 3 /4 Servo Motors Controlled.

5. Filing options- Multihead weigher, Servo Auger, Volumetric Cup filler.

6. Latest Technology, Smooth Operation.

7. Upto 400 mm. roll width.

8. Power Needs- 440 VAC, 7 kW.

9. Compressed air needs- 2-3 cfm @ 6 bar.

Packaging machine suitable for center seal and side gusset pouches, offering smooth, servo-controlled operation with multihead weighing for free-flow products, and output up to 100 pouches/min.

1. Suitable to make center seal / Side gusset pouches.

2. Available with Pneumatic / Single / Double / Three / Four Servo Motor Controlled.

3. Multihead weigh filler for Snacks, Granules, Grains & other free flow items.

4. Latest Technology, Smooth Operation Upto 900 mm. roll width- By different models.

5. Upto 100 Pouches/min. (As per product)

6. Power Needs- 220 / 440 VAC, 8 kW.

Packaging machine suitable for center seal and side gusset pouches, equipped with servo auger filling for powders and semi-powders, offering smooth, servo-controlled operation with output up to 90 pouches/min.

1. Suitable to make center seal / Side gusset pouches.

2. Available with Pneumatic / Single / Double / Three / Four Servo Motors Controlled.

3. Servo Auger filler for Powders & Semi-Powders.

4. Latest Technology, Smooth Operation.

5. Upto 900 mm. roll width- By different models.

6. Upto 90 Pouches/min. (As per product)

7. Power Needs- 220 / 440 VAC, 5 kW.

Packaging machine suitable for 4-corner seal (Quad) pouches, available with pneumatic or up to three servo motor control, supporting multiple filling options and delivering smooth operation with output up to 50 pouches/min.

1. Suitable to make 4 Corner seal (Quad) pouches.

2. Available with Pneumatic / Single / Double / Three servo motor Controlled.

3. Filing options- Multihead weigher, Servo Auger, Volumetric Cup filler.

4. Latest Technology, Smooth Operation.

5. Upto 700 mm. roll width- By different models.

6. Upto 50 Pouches/min. (As per product)

7. Power Needs- 220 / 440 VAC, 8 kW.

Automatic vertical form fill seal (collar type) machine with volumetric cup filler is specially designed to pack free flow salt & detergent powder. Machine does not have pulling belts, it is done by sealers. You can save money & maintenance by this technology.

1. Machine - Automatic VFFS packing machine to pack Salt,

2. Sealing type - Centre seal, Pillow pouch,

3. Packaging film - Heat sealable laminated film in roll form,

4. Film draw mechanism - By sealing jaws to avoid pulling belts consumption,

5. Electric Controls - PLC with touch screen HMI,

6. Contact Parts - Stainless Steel 316,

7. Electrical requirement - 3 Phase, 440 VAC +/- 10%, 5 kW,

8. Compressed Air required - 3-4 cfm @ 5 Kg/cm sq

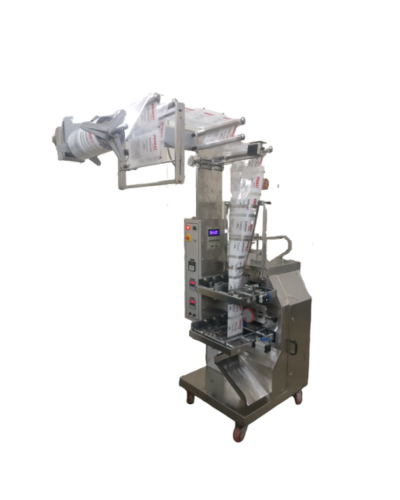

Automatic Vertical Form Fill Seal Machines are used to pack Grains and Granules as Tea, Coffee, Rice, Pulses, Dalia, Suji, Tobacco, Spices, Namkeens, Granules etc upto 500 Gms.

1. Automatic packing machine to pack Granules,

2. Packaging film - Heat sealable laminated film in roll form,

3. Maximum roll width - 340 mm,

4. Sealing Impression - Male-female linings on all sealing,

5. Electric Controls - Digital soft touch control panel,

6. Compressed air - 1-2 cfm at 5 Kg-cm2,

7. Electrical requirement - Single phase, 230 VAC +/- 10%, 3-4 kW.

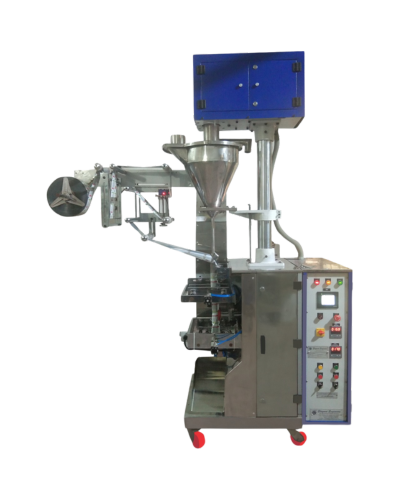

Automatic Vertical Form Fill Seal Machines with Servo motor controlled Auger filler is used to pack Powder as Spices Powder, Milk Powder, Coffee powder, Flour, Maida, Besan, Sattu, Chemicals and Pesticides etc upto 250 Gms. (with different models).

1. Automatic packing machine to pack Powder,

2. Packaging film - Heat sealable laminated film in roll form,

3. Sealing Impression - Male-female linings on all sealing,

4. Electric Controls - Digital Touch screen HMI & PLC,

5. Compressed air - 1-2 cfm at 6 Kg-cm2,

6. Electrical requirement - 3 phase, 440 VAC & Single phase, 230 VAC +/- 10%, 5-6 kW.

Automatic Vertical Form Fill Seal Machines with Piston filler is used to pack Liquid & Semi-Liquid as Oil, Shampoo, Ketch-up, Cream, Face wash, Liquid soap, Chemicals etc upto 200 ml

Automatic PFFS Machine With Auger Filler & Cup Filler For Small Pouches.

1. Suitable to pack all types of free flow Granules & Powder together in a pouch,

2. Roll width from 40 to 350 mm. (By different Models),

3. Speed- upto 80 Pouches per Min. (Depends upon weight & product),

4. Center seal & three side seal pouch by same machine,

5. Pneumatic controlled sealing and pulling,

6. Heavy duty & durable,

7. Power required- 220 VAC, single phase,

8. Compressed air required- 1-2 cfm.

Semi-automatic Vertical Pneumatic Pouch sealing machine (with/without automatic conveyor) is a perfect & most suitable machine to seal Gusseted / Non-Gusseted laminated preformed pouches and available in 4 models.

1. Suitable for Sealing of Laminated pouches,

2. Any type of laminated preformed pouch (Three side/ four side / center seal / Stand up etc) can be used on this machine,

3. Maximum Sealer Length - 600 mm,

4. Sealing type - Continuous heat type sealing jaws with male-female linings,

5. Electrical requirement - Single phase, 230 VAC +/- 10%, 2 kW,

6. Filling System - Any filling system can be attached.

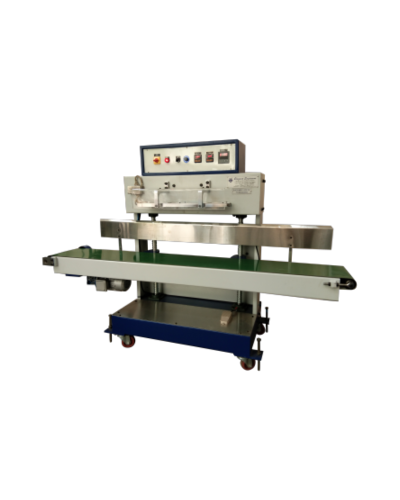

Semi-automatic Horizontal Pouch Sealing machine (Band sealer) is suitable for sealing of laminated as well as virgin films preformed pouches upto 14 inch long.

1. Machine - Heavy Duty Horizontal continuous pouch sealing machine,

2. Sealing type - Continuous heat type sealing jaws,

3. Packaging Pouches - All types of laminated / LDPE preformed pouches,

4. Electrical requirement - Single phase, 230 VAC +/- 10%, 2 kW,

5. Filling System (Optional) - Any filling system can be attached with this machine,

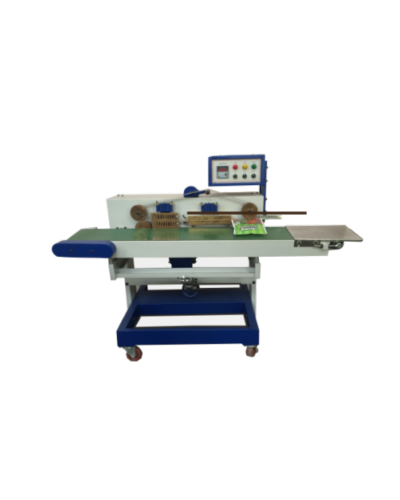

Semi-automatic Vertical Pouch sealing machines (Band sealer) are suitable for sealing of laminated as well as virgin films preformed pouches upto 45 inch long and available in 5 different models.

1. Sealing range - Adjustable, 18 to 45 inches pouch length can be sealed,

2. Length adjustment - Main body can be adjusted up & down by hand wheel as per pouch length,

3. Sealing Process - By moveable Teflon Belts,

4. Sealing type - Continuous heat type sealing jaws,

5. Packaging Pouches - All types of laminated / LDPE preformed pouches,

6. Electrical requirement - Single phase, 230 VAC +/- 10%, 3 kW,

7. Filling System - Any filling system can be attached with this machine.

Semi-automatic Vacuum, Nitrogen flushing and sealing machine is suitable for increasing the shelf-life of products through Vacuum & Nitrogen process as Chips, Dry Fruits, Snack food, Rice, Cheese, Sweets etc.

1. Sealing Process - Electronic Foot switch controlled,

2. Sealing type - Continuous heat type sealing jaws,

3. Packaging Pouches - All types of laminated preformed pouches,

4. Electrical requirement - Single phase, 230 VAC +/- 10%, 3 kW,

5. Compressed Air –1-2 cfm @ 6Kg./Cm.Sq

Loadcell controlled Linear weigh filler is used to weigh and fill free flows non-sticky material such as Tea, Tobacco, Rice, Pulses, Sugar, Seeds, Pasta, Macaroni, Vermicelli, Snack foods, Namkeens, Candy, Sweets, Dry Fruits, Biscuits etc. Available in single / Two / Four Heads upto 50 Kgs. Company provides Legal metrology certificate from weight & measurement dept. (Govt. of India) for all models.

1. Speed 10 Gms. to 25 Kgs. (By different size and models).

2. More Production Can add more heads for more production.

3. Power Required 220 VAC, single phase, 50 Hz, 3 kW.

4. Compressed air requirement requirement 5-6 kg. /cm sq.

5. Feeding system Linear vibrators are used for feeding the material.

6. Weigh unit Load cell controlled weigh filler unit to get more accuracy.

7. Optional attachment infeed Conveyor (Belt / Bucket type).

Volumetric Cup Filling (Telescopic disc type) machine is used to fill free flow materials such as Pulses, Rice, Namkeens, Sugar, Pesticides, Spices, Snacks, Tea, Seeds, Detergent Powder, Salt, Granules etc upto 10 Kgs. (with different models).

1) Filling Capacity 1 Gm. to 10 kg. (By different size and models)

2) Contact Parts - Made of stainless steel.

3) Power Required - 220 VAC, 50 Hz, Single phase, 1 kW max.

4) Disc motion Continuous / clutch-brake controlled moving disc.

5) Compressed air No required.

Servo controlled Auger Filling machine is used to fill free flow Powder products as Milk Powder, Spice Powder, Flour, Maida, Besan, Sattu, Pre-mix Powder, Chemicals etc upto 10 Kgs. (with different models).

1) Filling : Capacity 10 gm. to 10 Kg. (By different models)

2) Filling Speed 4 to 80 fillings per minute (depending on the product characteristics and weight)

3) Volume control Clutch brake / servo motor Controlled Auger Screw.

4) Motor Servo / AC induction motor (for Screw), 3 phase, 440 V AC (for Stirrer)

5) Power Required 3 phase, 440 VAC, 3 kW max.

6) Stirrer A opposite direction stirrer moves in the hopper for better filling.

7) Contact Parts Made of stainless steel.

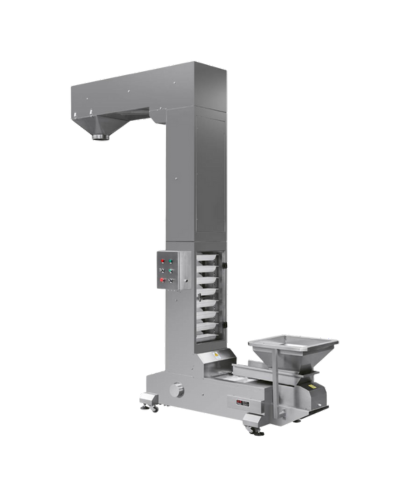

Infeed bucket / Belt conveyor is used to feed materials in upper hopper of filling machines. It is suitable for Sugar, Rice, Tea, Pulses, Snack Foods, Seeds, Namkeens, Dry Fruits, Grains and Granules and available in 3 different models according to product to be feed.

Screw feeding Conveyor is used to feed Powder materials in upper hopper of filling machine. It is suitable for Flour, Milk powder, Spice powder, Besan, Maida, Pesticides, Chemicals & other powder products. Available in 2 different models according to product to be feed.

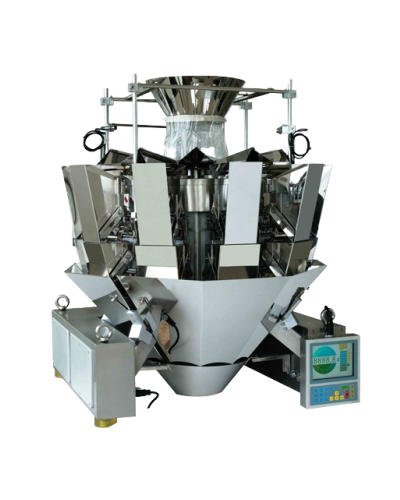

It is a high accuracy weighing & filling machine. It is used to weigh and fill free flows non-sticky material such as Tea, Rice, Pulses, Sugar, Seeds, Pasta, Vermicelli, Macaroni, Snack Foods, Namkeens, Candy, Sweets, Dry Fruits, Biscuits, Frozen Foods, Ice Cubes, Detergent Powder etc upto 20 Kgs. (By different models). Company provides Legal metrology certificate from weight & measurement dept. (Govt. of India) for all models.

Automatic Linear Pick, Fill and Seal machine to pack Powder & Granules from 2 to 10 Kgs. in Preformed Pouches / Bags

1. Suitable to pack Preformed Pouches as side seal, Bottom Gusset, with Dori etc.

2. Three stations Linear motion of pouches.

3. Pouch limits- Width- 240-400 mm.

4. Length- 300-500 mm.

5. Filing options- Multihead weigher, Servo Auger, Volumetric Cup filler.

6. Upto 10-15 Pouches/min.

7. Power needs- 220 VAC, 5 kW.

8. Compressed air needs- 4-5 cfm @ 6 bar.

Loadcell Controlled Screw Type Weigh Filler With Stitching Machine to Pack 5 to 50 Kgs. In this machine user can use only Powder applications

1. Automatic Auger Screw type weigh Filler to fill Powder in Preformed Pouches.

2. Speed- Approx. - 180 to 240 bags per hour. (Depend upon product & weight)

3. Stitching / Sealing of bag - Any machine can be attached.

4. Bag Type - Open Preformed plastic / Non-Woven / Woven

5. Machine operation - Manual bag placing.

6. Hopper Capacity - Upto 200-300 Kgs.

7. Contact Parts - Stainless Steel 304.

8. Compressed Air needs - 2-3 cfm @ 6 bar.

Automatic Linear Pick, Fill and Seal Machine With Servo Motor Controlled Auger Filler to pack Powder Such As Besan, Milk Powder, Flour, Maida Etc.

1. Pouch length - 300 mm (Min.) x 500 mm (Max).

2. Pouch width - 240 mm (Min.) x 400 mm (Max.).

3. All types of laminated preformed pouches Pillow type, Side seal type, Bottom Gusset, with D-cut, with Rope etc.

4. Pouch picking, transferring and opening by vacuum.

5. Electrical & Weight Control by By touch screen HMI.

6. Accuracy - Upto +/- 1% (Depends upon weight & product).

7. Sealing type - Continuous heat sealing with male-female linings.

8. Contact Parts - Stainless Steel 304.

9. Air Supply requirement - 4-5 cfm @ 8 Kg/cm²

Automatic Servo Motor Controlled Auger Filler with Slat Conveyor to fill Powder Items In Paper Tin, Plastic Jars, Container, Bottles and Boxes.

1. Filling System - Servo motor controlled Auger Filler unit.

2. Filling Speed - Upto 20 fillings/min. (Depend upon product to be packed).

3. Electric Controls - PLC with touch screen HMI.

4. Contact Parts - Stainless Steel 304.Electrical requirement - Threephase, 440 VAC +/- 10%, 4 kW

Automatic Filling machine for granules items in jars, Paper Tins, Containers, Bottles & Boxes upto 1000 Gms.

Automatic Loadcell Controlled Gravity Type Weigh Filler to Pack granules items upto 50 Kgs.

1. Automatic gravity type weigh filler to fill granules in Preformed Bags / Pouches.

2. Speed- Approx. - 180 to 240 bags per hour. (Depend upon product & weight)

3. Stitching / Sealing of bag - Any machine can be attached.

4. Bag Type - Open Preformed plastic / Non-Woven / Woven

Machine operation - Manual bag placing.

6. Hopper Capacity - Upto 100-200 Kgs.

7. Contact Parts – Mild Steel / Stainless Steel 304.

8. Compressed Air required - 2-3 cfm @ 6-8 Kg/cm

Automatic Vertical Form Fill Seal Machines (Collar type) with volumetric Cup filler is used to pack free flow granules as Tea, Coffee, Spices, Rice, Pulses, Poha, Detergent Powder, Namkeens etc upto 10 Kgs.

1. Contact Parts All contact parts of the machine are made of Stainless Steel.

2. Sealing Type Center seal, Intermittent Type.

3. Packing Size Up to 300 mm. rol l width (Model: EE-CT 300), Up to 500 mm. roll width (Model: 4) EE-CT 500), Up to 700 mm. roll width (Model: EE-CT 700), Up to 900 mm. roll width (Model: EE-CT 900),

4. Film Type Heat sealable, Pet Poly.

5. Packing Range Up to 10 Kgs. (Depends upon product density).

6. Speed Up to 50 to 60 Pouches per min. (Depends upon product, weight)

7. Electric Control By PLC with touch screen HMI.

8. Photocell Unit For accurate pouch length.10)Paper Pulling By Pulling belts & Pneumatic Pressure.

9. Compressed Air 3-4 CFM at 10 kg. /sq.cm. is required.

10. Power Required Three phase, 440 VAC, 50 Hz, 5 kW.

11. Optional Attachment Batch coding device (Hot foil ribbon type). Nitrogen flushing unit, Infeed conveyor, Outfeed conveyor, Batch cutting unit, Pouch gusseting unit,

Automatic Vertical Form Fill Seal Machines (Collar type) with Loadcell Controlled Multihead Combination weigh filler (10/14/20/24 heads) is used to pack free flow Grains and Granules as Tea, Coffee, Spices, Rice, Pulses, Nuts, Candy, Dry fruits, Namkeens, Snack food etc upto 10 Kgs.

1. Contact Parts All contact parts of the machine are made of Stainless Steel.

2. Sealing Type Center seal, Intermittent Type.

3. Packing Size Up to 300 mm. roll width (Model: EE-CT 300) Up to 500 mm. roll width (Model: EE-CT 500) Up to 700 mm. roll width (Model: EE-CT 700) Up to 900 mm. roll width (Model: EE-CT 900)

4. Film Type Heat sealable, Pet Poly.

5. Packing Range Up to 5 Kgs. (Depends upon product density).

6. Speed Up to 60-70 Pouches per min. (Depends upon product, weight & No. of heads)

7. Electric Control By PLC with touch screen HMI.

8. Temp. Controller PID control, Digital 45 x 45 mm.

9. Photocell Unit For accurate pouch length.

10. Paper Pulling By Pulling belts & Pneumatic Pressure.

11. Feeding System Linier vibrator for feeding material.

12. Weight Control Very simple digital control panel.

13. Compressed Air 3-4 CFM at 8 kg. /sq.cm. is required.

14. Power Required Three phase, 440 VAC, 50 Hz, 5 kW.

15. Optional Attachment Batch coding device (Hot foil ribbon type). Nitrogen flushing unit, Infeed conveyor, Outfeed conveyor, Batch cutting unit, Pouch gusseting unit.

Automatic Vertical Form Fill Seal Machines (Collar type) with Servo motor controlled Auger filler is used to pack Powder as Spices Powder, Milk Powder, Coffee powder, Flour, Maida, Besan, Sattu, Chemicals and Pesticides etc upto 10 Kgs. (with different models).

1. Contact Parts- All contact parts of the machine are made of Stainless Steel.

2. Sealing Type - Center seal, Intermittent Type.

3. Packing Size - Up to 300 mm. roll width (Model: EE-CT 300) Up to 500 mm. roll width (Model: EE-CT 500) Up to 700 mm. roll width (Model: EE-CT 700) Up to 900 mm. roll width (Model: EE-CT 900)

4. Film Type Heat sealable, Pet Poly.

5. Packing Range Up to 10 Kgs. (Depends upon product density).

6. Speed Up to 60 Pouches per min. (Depends upon product to be packed)

7. Electric Control By PLC with touch screen HMI.

8. Temp. Controller PID control, Digital 45 x 45 mm.

9. Photocell Unit For accurate pouch length.

10. Paper Pulling By Pulling belts & Pneumatic Pressure

11. Feeding System Linear vibrator for feeding material.

12. Weight Control Very simple digital control panel and load cell.

13. Compressed Air 3-4 CFM at 10 kg. /sq.cm. is required.

14. Power Required Three phase, 440 VAC, 50-60 Hz.

15. Optional Attachment Batch coding device (Hot foil ribbon type). Nitrogen flushing unit Infeed conveyor Outfeed conveyor Batch cutting unit Pouch gusseting unit

Automatic Vertical Form Fill Seal Machines (Collar type) with loadcell controlled Linear weigh filler is used to pack free flow Grains & Granules as Tea, Coffee, Spices, Rice, Pulses, Nuts, Candy, Dry fruits, Namkeens, Snack food etc upto 10 Kgs.

1. Contact Parts- All contact parts of the machine are made of Stainless Steel.

2. Sealing Type - Center seal, Intermittent Type.

3. Packing Size - Up to 300 mm. roll width (Model: EE-CT 300) Up to 500 mm. roll width (Model: EE-CT 500) Up to 700 mm. roll width (Model: EE-CT 700) Up to 900 mm. roll width (Model: EE-CT 900)

4. Film Type Heat sealable, Pet Poly.

5. Packing Range Up to 10 Kgs. (Depends upon product density).

6. Speed Up to 60 Pouches per min. (Depends upon product, weight & no. of heads

7. Electric Control By PLC with touch screen HMI.

8. Temp. Controller PID control, Digital 45 x 45 mm.

9. Photocell Unit For accurate pouch length.

10. Paper Pulling By Pulling belts & Pneumatic Pressure

11. Feeding System Linear vibrator for feeding material.

12. Weight Control Very simple digital control panel and load cell.

13. Compressed Air 3-4 CFM at 10 kg. /sq.cm. is required.

14. Power Required Three phase, 440 VAC, 50-60 Hz.

15. Optional Attachment Batch coding device (Hot foil ribbon type). Nitrogen flushing unit Infeed conveyor Outfeed conveyor Batch cutting unit Pouch gusseting unit

Automatic Vertical Form Fill & Seal (Collar type) for four corner seal (Quad) pouch machines is a perfect & most Suitable machine to pack Powder & Granules products in four corner seal (Quad seal) Pouches and Four corner with center seal (Panta seal) Pouches. The products like Tea, Spices, Rice, Coffee, Pulses, Namkeens, Snack Food, Dog food, Nuts, Dry Fruits etc. This machine can make different sealing options as a) Four corner seal with side gusset, b) Four corner and center seal with side gusset, 3) Center seal pillow pouch, 4) Center seal with side gusset. This machine can effectively handle packaging of products upto 5 Kgs.

1. Suitable to make 4 Corner seal (Quad) pouches.

2. Available with Pneumatic / Single / Double / Three servo motor Controlled.

3. Filing options- Multihead weigher, Servo Auger, Volumetric Cup filler.

4. Latest Technology, Smooth Operation

5. Upto 700 mm. roll width- By different models.

6. Upto 50-55 Pouches/min. (As per product)

7. Power Needs- 220 / 440 VAC, 8 kW.